About INOX Air Products – Powering India’s Growth Story

INOX Air Products (INOXAP) is India’s largest manufacturer of industrial, medical and electronic gases, with more than six decades of experience in the gases business. From oxygen in hospitals to nitrogen in steel plants and specialty gases for electronics, the company is deeply integrated into India’s industrial and healthcare backbone.

The company was originally founded in 1963 as Industrial Oxygen Company Ltd in Pune by the Jain family. In 1999, the INOX Group entered into a joint venture with Air Products & Chemicals Inc., USA, creating INOX Air Products as we know it today. This Indo–US partnership has grown into one of the longest-running collaborations in India’s manufacturing sector.

Headquartered in Mumbai, INOXAP operates 50+ plants and locations across the country and has the capacity to produce over 4,700 tonnes per day of liquid gases. Its product portfolio includes oxygen, nitrogen, argon, hydrogen, helium, nitrous oxide and a wide range of ultra-high purity and specialty gas mixtures used in advanced industries.

Over the years, the company has shifted from simply “selling gases” to offering complete solutions — on-site air separation units (ASUs), bulk delivery systems, pipeline networks and technical services that ensure reliability and purity for customers in steel, pharmaceuticals, electronics, energy, food processing and many other sectors.

During the COVID-19 pandemic, INOXAP played a major role in supplying medical oxygen across India, using its large production capacity and cryogenic tanker fleet to support hospitals. Today, the same expertise in high-purity gases is being directed towards India’s next big push — clean energy, solar manufacturing and semiconductors — and Dholera is at the centre of this new chapter.

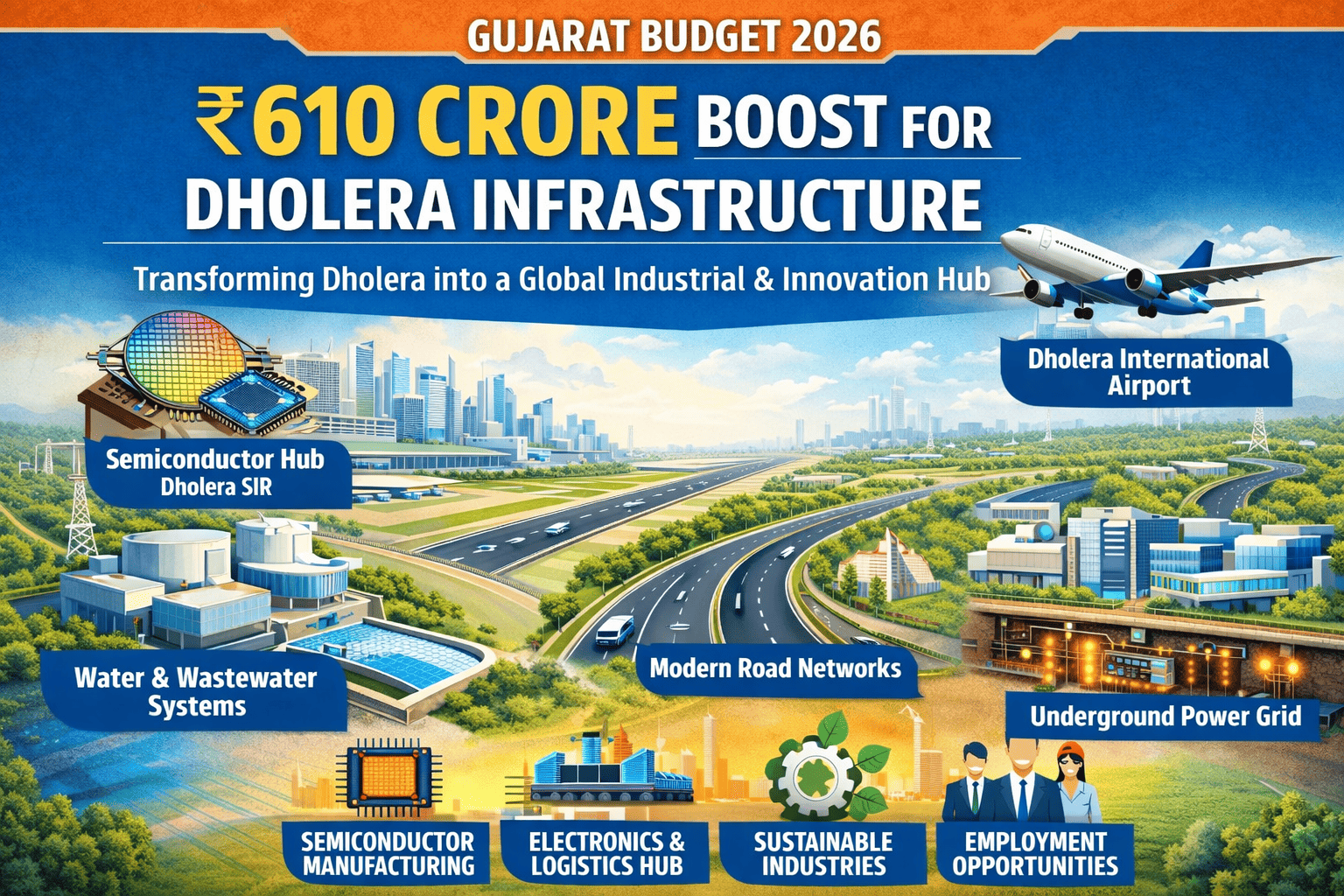

INOX Air Products’ Contribution to Dholera’s Industrial Growth

1. Supplying UHP Nitrogen to ReNew’s TOPCon Solar Cell Facility

ReNew Photovoltaics is setting up a large 4 GW TOPCon solar cell manufacturing facility at Dholera in Gujarat. INOX Air Products has signed a long-term agreement with ReNew to supply ultra-high purity (UHP) nitrogen to this plant.

To meet this demand, INOXAP will build a dedicated state-of-the-art Air Separation Unit (ASU) in Dholera. The ASU is designed to continuously supply nitrogen at extremely high purity levels, matching the strict standards required for high-efficiency TOPCon solar cell manufacturing. The unit is expected to be fully operational by the end of next year, timed with the ramp-up of ReNew’s facility.

Nitrogen may sound like a simple gas, but in solar cell production it is critical. TOPCon cells are very sensitive to oxygen and moisture; even small contamination can damage wafer surfaces or key layers. UHP nitrogen is used to create a clean, inert atmosphere inside furnaces and process chambers, keeping oxygen and humidity away and protecting the delicate surfaces of the cells.

By assuring 24×7 supply of UHP nitrogen through a dedicated ASU and pipeline, INOXAP is making it possible for ReNew to run a world-class manufacturing line in Dholera. Reliable gas infrastructure reduces downtime, improves yields, and gives global customers confidence that modules coming out of Dholera meet international quality standards.

For Dholera, this partnership means more than just one supply contract. It positions the region as a serious player in upstream solar manufacturing — not just solar parks, but also the advanced factories that make cells and modules. This aligns strongly with India’s goal of cutting dependence on imported solar equipment and building a domestic supply chain.

2. Building an Electronic Specialty Gas Hub in Dholera

INOXAP is not stopping with one ASU. The company has announced a major ₹500 crore investment to build an Electronic Specialty Gas Hub in Dholera. It has already acquired a strategic land parcel in the region and begun planning and construction.

This hub will manufacture and supply ultra-high purity bulk and specialty gases — including nitrogen, oxygen, argon and hydrogen — that are essential for semiconductor fabrication and other high-tech industries. Designed as both a production and fulfilment centre, the facility aims to provide contamination-free, reliable gas delivery to fabs and outsourced semiconductor assembly and test (OSAT) units across India.

The hub has a clear customer anchor: the semiconductor ecosystem being built around Tata Electronics’ upcoming chip fabrication plant in Dholera. Tata Electronics is developing India’s first semiconductor fab here, a project of around ₹91,000 crore in partnership with Taiwan’s Powerchip Semiconductor Manufacturing Corp. INOXAP’s Dholera hub is being designed to cater to the complex gas needs of this fab and other smaller semiconductor players in the region.

Initially, the hub will import many of the 40+ specialty gases that are not currently produced in India, store them safely, and deliver them to customers. Over time, with technology partnerships and rising demand, INOXAP plans to manufacture more of these gases domestically and even export them from Dholera, turning the city into a regional hub for high-purity gases and chemicals.

3. Skills, Jobs and Local Economic Impact

Industrial growth is not only about plants and pipelines; it is also about people. INOXAP already employs over 1,800 people, and the company is increasing its workforce as it expands new projects like the Dholera hub.

For solar and semiconductor gases, the skill requirements are highly specialised. INOXAP has been sending its employees abroad to vendor locations for hands-on training in managing complex gas systems and ultra-high purity standards. These trained professionals then return to India and form the core technical team for new facilities like Dholera.

As the ASU for ReNew, the electronic gas hub, and associated logistics and maintenance operations come online, Dholera can expect:

- Direct jobs in operations, quality control, engineering, logistics and safety

- Indirect jobs in construction, support services, transport, packaging, maintenance and utilities

- Skill development in advanced process control, gas handling, cleanroom standards and safety systems

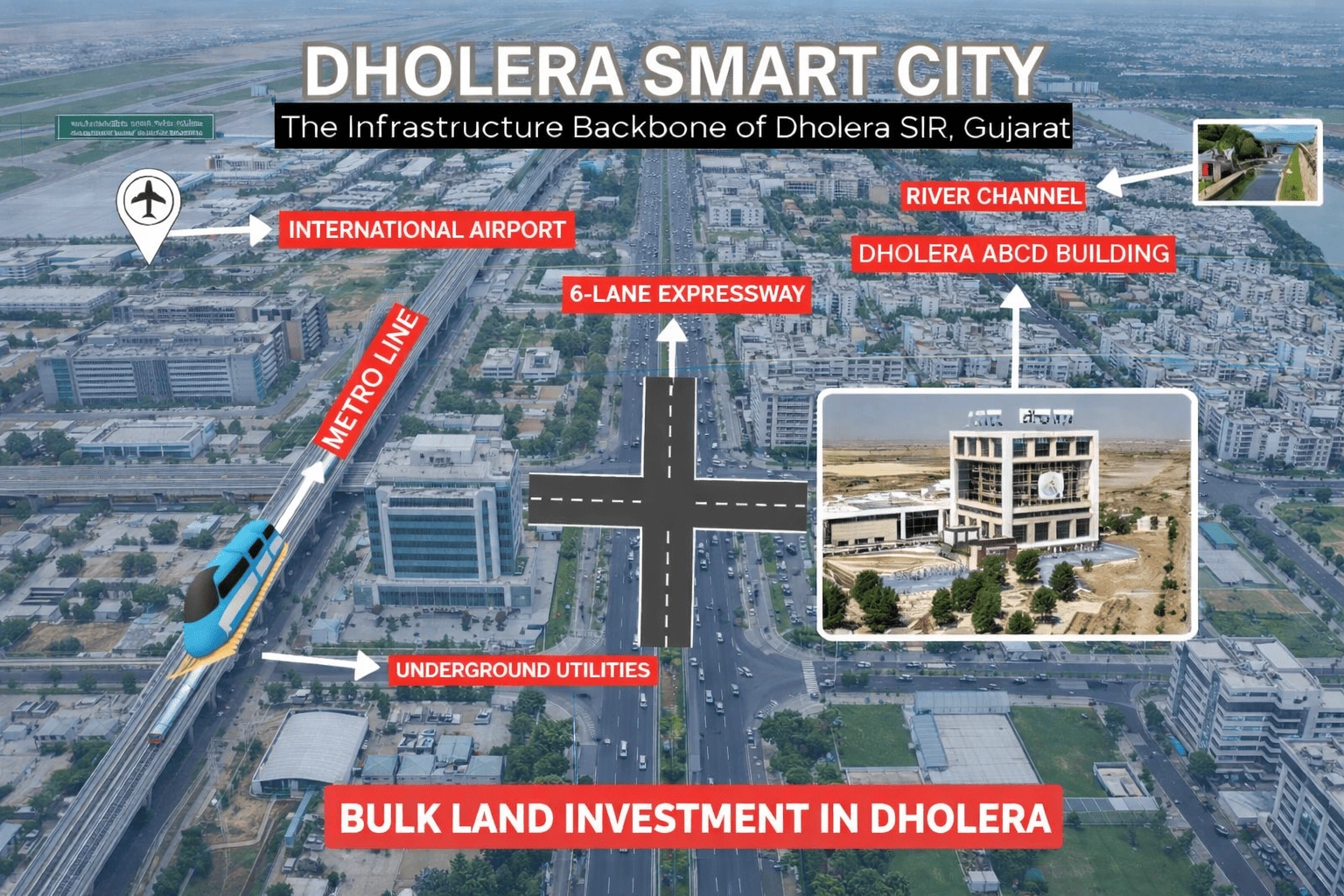

All of this supports the vision of Dholera SIR as a smart industrial region, not just a real estate story. The presence of a large, experienced gas supplier like INOXAP also lowers the entry barrier for other advanced manufacturers who may now consider Dholera as a location, because critical utilities (like UHP gases) are already available.

How INOX Air Products is Transforming Industrial Growth in Dholera

INOX Air Products acts as a hidden backbone for Dholera’s new industries. Its projects create a multiplier effect that goes far beyond the gas plants themselves.

Making Dholera “fab-ready” and “cell-ready”

- The dedicated ASU for ReNew’s 4 GW TOPCon solar cell plant ensures that one of India’s largest upcoming solar manufacturing facilities has world-class gas infrastructure within Dholera itself.

- The electronic specialty gas hub is being built specifically to support the Tata Electronics semiconductor fab and other chip-related units, giving Dholera the critical utility backbone that every global fab requires.

Strengthening India’s clean energy and semiconductor value chains

- By supplying UHP nitrogen and other gases domestically, INOXAP helps reduce India’s dependence on imported gases and chemicals that are often expensive and vulnerable to supply shocks.

- Stable gas supply enables manufacturers to run continuous operations, improve yields and meet export-quality standards in solar cells, modules and chips.

Boosting investor confidence in Dholera SIR

- When a leading gas company commits ₹500 crore for a long-term hub and also signs multi-year supply contracts with top players like ReNew, it sends a strong signal that Dholera is a serious, future-ready industrial zone.

- This, in turn, attracts more investors in allied sectors such as equipment suppliers, cleanroom builders, logistics providers and component manufacturers.

Driving inclusive regional development

- New plants bring roads, utilities, training centres and service businesses around them. With both solar and semiconductor ecosystems now taking shape, Dholera can evolve into a high-tech cluster that offers long-term, high-skill employment rather than only low-value jobs.

In simple terms, INOX Air Products is laying the “invisible infrastructure” — pure gases, reliable supply, speciality utilities and skilled manpower — that makes visible infrastructure like factories and technology parks possible.

Conclusion

The partnership between INOX Air Products and ReNew’s TOPCon solar cell facility, combined with INOXAP’s ₹500 crore electronic specialty gas hub, marks a turning point in Dholera’s industrial journey. UHP nitrogen supply to the ReNew plant ensures that Dholera will host one of India’s most advanced solar cell manufacturing lines, while the gas hub prepares the city to support Tata Electronics’ semiconductor fab and other high-tech industries.

For Dholera, this is more than just another investment announcement. It is proof that the region is moving from plans on paper to real factories, real jobs and real technology. INOX Air Products brings decades of expertise, nationwide scale and deep understanding of high-purity gases to the city. That expertise will quietly support every wafer, every cell and every chip manufactured here.

As more projects go live, Dholera is likely to emerge as a powerful combination of clean energy hub and semiconductor hub — and INOX Air Products will remain one of the key enablers behind this industrial growth story.